189-1422-7001

![]() PRODUCT FEATURES

PRODUCT FEATURES

1. Three-beam four-column structure

2. Cartridge valve control to improve efficiency

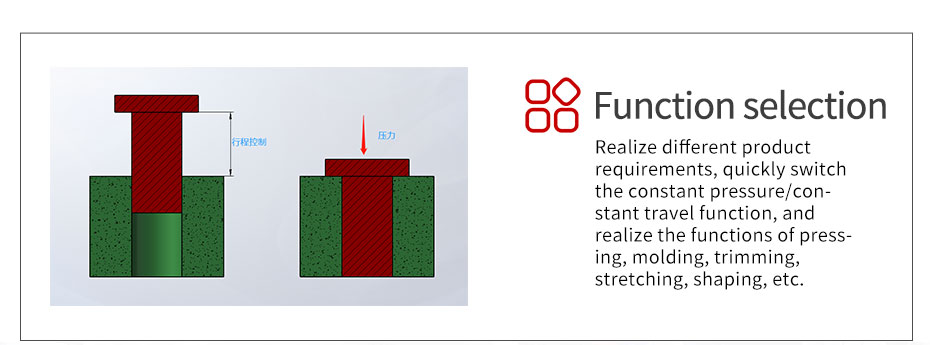

3. It can realize constant pressure and constant range process Efficient water cooling device to meet continuous production

![]() APPLICABLE PRODUCTS

APPLICABLE PRODUCTS

Radiator and computer box

![]() OPTIONAL COMPONENTS

OPTIONAL COMPONENTS

1. Photoelectric protection device

2. Mobile workbench

3. Floating guide rail and rolling bracket for mold change

4. Blanking buffer device

5. Mold quick clamping mechanism

6. Industrial touch screen

7. Stroke, pressure and speed digital display control device

8. Water cooling device, displacement sensing device

9. The four corners of the blank holder slider and hydraulic pad are respectively pressure regulating devices (stretching asymmetric parts

)

![]() 技术参数/ TECHNICAL PARAMETER

技术参数/ TECHNICAL PARAMETER

model | Company | 40T | 63T | 100T | 160T | 200T | 315T | 400T | 500T | ||

Nominal force | KN | 400 | 630 | 1000 | 1600 | 2000 | 3150 | 4000 | 5000 | ||

Jacking force | KN | 63 | 100 | 200 | 250 | 400 | 630 | 630 | 1000 | ||

Maximum working pressure of liquid | Mpa | 25 | 25 | 26.2 | 26 | 25 | 25 | 25 | 26 | ||

Slide stroke | mm | 400 | 500 | 500 | 500 | 700 | 800 | 800 | 900 | ||

Maximum opening height | mm | 600 | 700 | 900 | 900 | 1120 | 1250 | 1400 | 1500 | ||

Table size | around | mm | 400 | 500 | 580 | 800 | 900 | 1200 | 1200 | 1400 | |

about | mm | 400 | 500 | 710 | 800 | 900 | 1200 | 1260 | 1400 | ||

Ejection stroke | mm | 120 | 160 | 200 | 200 | 250 | 300 | 300 | 300 | ||

Slider speed | No load down | mm/s | 40 | 76 | 100 | 100 | 100 | >100 | >100 | >100 | |

No load down | mm/s | 10 | 10 | 8-15 | 8-15 | 8-15 | 8-15 | 8-15 | 10 | ||

return trip speed | mm/s | 60 | 60 | 60 | 60 | 70 | 70 | 70 | 80 | ||

Overall dimension of machine tool | around | mm | 1000 | 1100 | 1200 | 1600 | 2120 | 2220 | 2220 | 2420 | |

about | mm | 1484 | 1900 | 2076 | 2650 | 2780 | 3440 | 3440 | 4100 | ||

Height above ground | mm | 2406 | 2430 | 3300 | 3350 | 3690 | 3900 | 4050 | 5348 | ||

Motor power | KW | 5.5 | 5.5 | 7.5 | 15 | 18.5 | 22 | 22 | 37 | ||

Total weight (approx.) | T | 2 | 2.7 | 4.2 | 7.2 | 12 | 15.2 | 20.2 | 30.2 | ||

model | Company | 630T | 1000T | 1250T | 1600T | 2000T | ||

Nominal force | KN | 6300 | 10000 | 12500 | 16300 | 20000 | ||

Jacking force | KN | 1000 | 1000 | 1000 | 1200 | 2000 | ||

Maximum working pressure of liquid | Mpa | 26 | 26 | 26 | 26 | 27 | ||

Slide stroke | mm | 900 | 900 | 900 | 900 | 1400 | ||

Maximum opening height | mm | 1500 | 1500 | 1500 | 1600 | 1600 | ||

Table size | around | mm | 1500 | 1600 | 1600 | 1600 | 2000 | |

about | mm | 1500 | 1600 | 1800 | 2000 | 2800 | ||

Ejection stroke | mm | 400 | 400 | 400 | 450 | 450 | ||

Slider speed | No load down | mm/s | >100 | >100 | >100 | >100 | >100 | |

work speed | mm/s | 10 | 12 | 15 | 10 | 10 | ||

return trip speed | mm/s | 65 | 80 | 80 | 75 | >75 | ||

Overall dimension of machine tool | Front and rear | mm | 2520 | 3000 | 3800 | 4000 | 3500 | |

about | mm | 4390 | 2340 | 5250 | 5800 | 5900 | ||

Height above ground | mm | 5600 | 5800 | 6000 | 6500 | 8000 | ||

Motor power | KW | 45 | 68 | 75 | 90 | 134 | ||

Total weight (approx.) | T | 38.3 | 48.2 | 60 | 85 | 145 | ||

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设