Hydraulic press is actually a kind of hydraulic press! We know that the press is generally divided into pneumatic press and hydraulic press. Hydraulic press takes liquid as the medium. According to the different medium, it can also be divided into hydraulic press and hydraulic press.

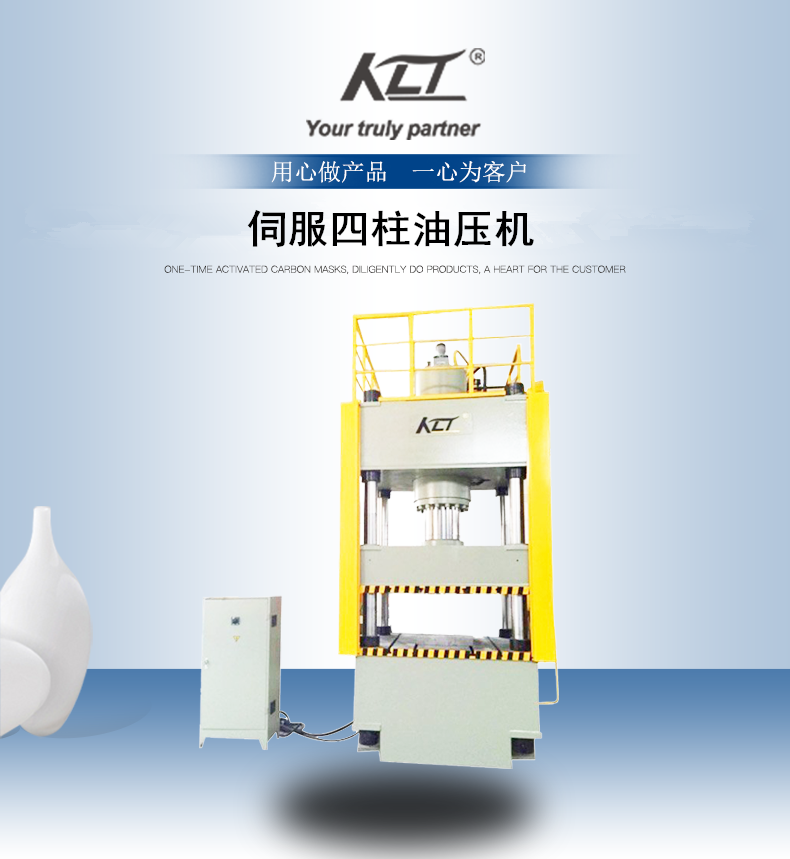

The traditional hydraulic press uses a constant displacement pump and a variable displacement pump, while the servo hydraulic press uses a servo motor to drive a gear pump. Its advantages are high efficiency, energy saving, noise reduction, and improved equipment accuracy. Take a Xuzhou Forging 500t oil press as an example:

Before the transformation, use a manipulator to load and unload materials, and make a shallow stretching of the ice back of the refrigerator. The operating pressure is about 10-12Mpa. The equipment uses two 30 'kw motors to drive two 63Ycy14 motors, 22 hours a day. The single semi-automatic loading and unloading cycle of the manipulator is about 25 seconds, the equipment's own beat is 16 seconds, and the output is about 22 hours. 3000 pieces a day. The equipment has high heat, serious oil leakage, high noise and high energy consumption.

After the transformation, the equipment's own rhythm is 9 seconds, plus the manipulator's feeding and unloading rhythm is 14 seconds, and the output is about 3600 pieces in 20 hours. The equipment has low heat, no oil leakage, and no noise. According to the calculation results, after upgrading to servo hydraulic press, the energy consumption per unit product is reduced by 60%, the efficiency is increased by 40%, and the noise is reduced by 80%. According to the difference of processing technology and production rhythm, servo driven hydraulic presses can save 30-70% electricity compared with traditional hydraulic presses.

Other highlights of servo hydraulic press:

1. The repetitive positioning accuracy is high, up to 0.01mm. The pressure closed-loop control has high accuracy. Timely monitoring of oil temperature and hydraulic pressure, high response speed and accurate control and positioning.

2. The man-machine interface is friendly, and the pressure, position and speed can be adjusted on the computer screen. Programming is simple. Operator, administrator and manufacturer multi-user interface realize password management.

3. Equipment protection, reduce the impact of mold opening and locking, and extend the service life of mechanical equipment and abrasives.

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设