189-1422-7001

![]() Product introduction

Product introduction

1. A new generation of numerical control hydraulic press, four-column guide body steel plate welding. Applicable process, SMC, DMC, BMC plastic products molding.

2. It is applicable to medium-sized parts in automobile, yacht, hardware, aviation, electronics, electrical appliances and other industries.

3. The servo motor and high-precision oil pump drive the pressure, speed and exhaust in sections.

4. PLC programming, touch screen display, control.

5. Precision control of displacement, speed and pressure sensors can be adjusted on the industrial touch screen.

6. Provide remote network service, and the machine will automatically alarm for fault and maintenance.

![]() Product features

Product features

1. High efficiency and energy saving. The power consumption is 30% - 50% less than that of ordinary motors.

2. Low noise, noise can be controlled at about 60 dB.

3. The working position, speed and pressure can be adjusted infinitely.

4. Fast response, high pressure and position repetition accuracy.

5. High efficiency, multiple internal protection and extremely low failure rate.

6. 12 hours of continuous operation does not require cooling oil temperature.

7. The pipes and joints shall adopt SEA international standards to prevent pipeline oil leakage.

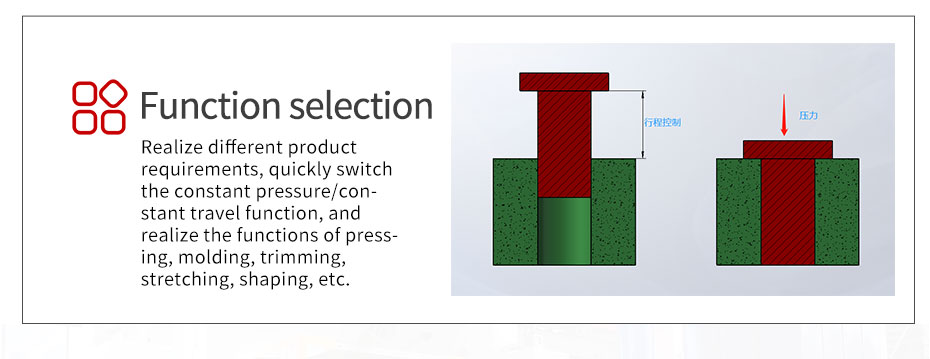

8. The button centralized control, (constant travel/constant pressure) two control modes and (adjustment/automatic) two operation modes are adopted.

9. European CE standard hydraulic system and electrical safety IP54 level.

![]() Scope of application

Scope of application

Applicable to: medium and large electric motors, automobiles, machine tools, aviation, electronics, electrical appliances, hardware and other parts.

1. (For example, HPFS-100T) is mainly applicable to press fitting and assembly of bearings or sleeves of various parts. Trimming, forming, stamping and sealing of medium and large parts and components.

2. (For example, HPFS-100T/20T-E) is mainly used for the pressing and forming process of metal materials, such as sheet drawing, flanging, trimming and forming of medium and large metal parts.

3. (For example, HPFS-100T/40T-C) is mainly used for metal stretch forming process, such as sheet drawing and forming of medium and large metal parts.

4. This series of machines has high degree of automation, high stability, energy saving and low noise. It is the latest machine to replace the traditional hydraulic press, especially suitable for mass production of parts.

![]() technical parameter

technical parameter

| name | Jacking pressure | Hydraulic pad pressure | Motor power | Fast speed | Working speed | Return speed | working pressure | Maximum draft force | Ejection speed | Return speed | Ejection stroke | Table size (L.R) | Table size (F.B) | Opening height | cylinder stroke | weight |

| Optional | Optional | KW | mm/s | mm/s | mm/s | Mpa | KN | mm/s | mm/s | mm | mm | mm | mm | mm | T | |

| HPFS-40T | 4T | 10T | 8 | 260 | 20 | 150 | 24.5 | 55 | 10-42 | 83 | 100 | 400 | 400 | 600 | 400 | 2.5 |

| HPFS-60T | 6T | 25T | 8 | 220 | 18 | 175 | 21 | 64 | 10-43 | 72 | 200 | 500 | 500 | 700 | 500 | 4 |

| HPFS-90T | 10T | 40T | 15 | 230 | 18 | 200 | 25 | 87 | 10-43 | 88 | 200 | 710 | 580 | 900 | 500 | 5 |

| HPFS-160T | 16T | 60T | 18.5 | 210 | 16 | 230 | 24.5 | 126 | 10-41 | 75 | 250 | 800 | 800 | 900 | 500 | 7 |

| HPFS-200T | 25T | 100T | 18.5 | 260 | 15 | 250 | 24 | 126 | 10-35 | 74 | 250 | 900 | 900 | 1000 | 700 | 8.5 |

| HPFS-250T | 25T | 100T | 18.5 | 330 | 17 | 150 | 24 | 274 | 10-43 | 93 | 250 | 900 | 900 | 1000 | 700 | 10 |

| HPFS-300T | 40T | 160T | 36 | 330 | 13 | 140 | 25 | 306 | 10-34 | 69 | 300 | 1300 | 1200 | 1200 | 800 | 18 |

| HPFS-400T | 40T | 200T | 28.3 | 330 | 13 | 140 | 25 | 306 | 10-33 | 75 | 300 | 1240 | 1200 | 1300 | 800 | 19 |

| HPFS-500T | 60T | 250T | 29 | 330 | 13 | 140 | 25 | 306 | 10-34 | 77 | 300 | 1700 | 1300 | 1200 | 900 | 25 |

| HPFS-600T | 100T | 300T | 40 | 300 | 17 | 145 | 25 | 720 | 10-34 | 89 | 400 | 1800 | 1400 | 1300 | 900 | 40 |

| HPFS-800T | 100T | 400T | 40 | 300 | 14 | 130 | 25 | 820 | 10-26 | 76 | 400 | 1800 | 1400 | 1300 | 900 | 45 |

| HPFS-1000T | 160T | 500T | 33.9 | 350 | 14 | 110 | 25 | 1200 | 10-28 | 75 | 400 | 2800 | 1600 | 1600 | 900 | 80 |

| HPFS-1200T | 200T | 600T | 45 | 350 | 13 | 100 | 25 | 1600 | 10-27 | 80 | 400 | 3600 | 1800 | 1600 | 900 | 90 |

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设