189-1422-7001

![]() PRODUCT INTRODUCTION

PRODUCT INTRODUCTION

Box class or larger categories of aluminum alloy, magnesium alloy parts fly edge, casting edge cutting with medium tonnage rapid hydraulic edge cutting machine or servo, main edge cutting tonnage of in 60T-160T, the original main use manual up and down, but because of large workpiece die casting time is long, die casting temperature is high, artificial up and down material is not convenient, loading and unloading time is too long, cause high cost, low efficiency. Now use the automatic manipulator in the die after casting automatic material into the automatic edge cutting machine edge cutting, the manipulator automatic material completion, put into the transmission line into the next process, forming a fast unmanned operation of the production line, greatly improve the production efficiency, compared with the output of the original production process increased 2-3 times. To improve production efficiency requires stable and efficient production equipment, so our company focuses on the development of such production line so the key supporting equipment and die, using imported automatic manipulator, efficient and stable CNC servo edge cutting machine, supporting edge cutting die.

![]() PRODUCT FEATURES

PRODUCT FEATURES

1, with the die-line assembly line production, automatic material into the edge cutting machine.

2, fast CNC edge cutting machine is fast, the automatic error prevention function, efficiency increased by about 2 times.

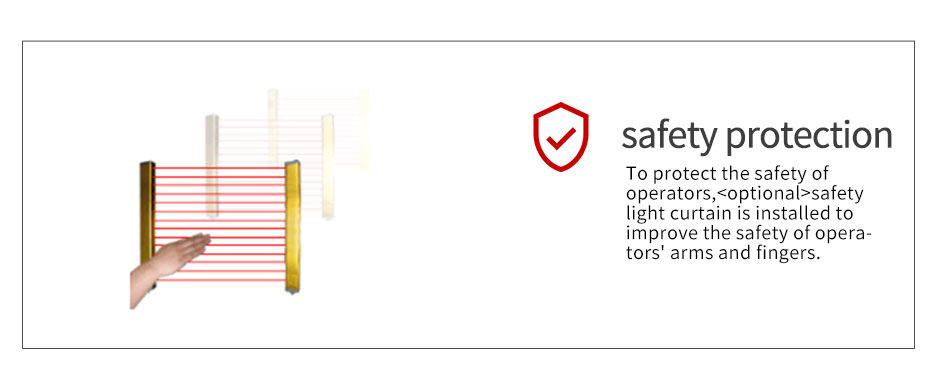

3. Shorten the time for operators to take and put materials manually, causing the scrap of the finished product, which improves the safety of personnel and improves the yield rate of the workpiece. Composition of production line: die casting machine automatic manipulator servo CNC edge cutting machine conveying line, die casting die cutting die, etc.

![]() PERFORMANCE BENEFITS

PERFORMANCE BENEFITS

1, significant energy saving, improve efficiency, energy saving of 30-50%.

2. Low noise, environmental protection, and effectively improve the working environment.

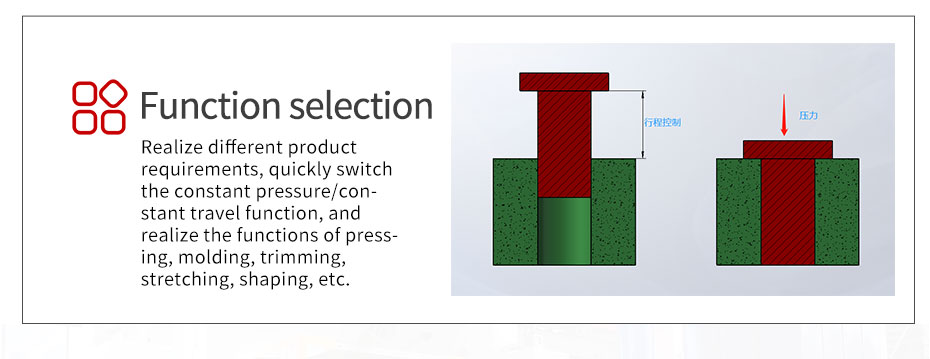

3, the use of electro-hydraulic servo system, pressure, stroke control accuracy, fast reaction speed.

4, digital arbitrary adjustment, setting, save the position of the machine, speed and pressure.

5. Use the electro-hydraulic servo system control to effectively reduce the oil temperature, the pipeline will not leak oil, and prolong the service life of the machine.

6, the workpiece placement automatic error prevention function. You can prepare different process actions and save 100 parts process parameters. Integrated servo hydraulic edge cutting machine above many advantages and characteristics, the overall perfect ordinary hydraulic edge cutting machine has many problems and at the same time meet the requirements of the diversity of function, meet the manufacturer demand for different die-casting products, achieve efficient, convenient program automatic switch, improve the production efficiency and product quality.

![]() technical parameter

technical parameter

| HPFS series four-column fast servo hydraulic trimming machine | ||||||

| Model name | Company | 60T | 90T | 120T | 160T | |

| Nominal force | KN | 1600 | 900 | 1200 | 1600 | |

| Maximum opening distance | mm | 1000 | 1200 | 1200 | 1400 | |

| Hydraulic cylinder stroke | mm | 700 | 800 | 800 | 1000 | |

| Table size | about | mm | 1100 | 1300 | 1500 | 1500 |

| around | mm | 900 | 900 | 1000 | 1000 | |

| Slider | Fast down speed | mm/s | 300 | 250 | 300 | 300 |

| Working speed | mm/s | 5~18 | 5~18 | 5~20 | 5~16 | |

| Fast return speed | mm/s | 175 | 200 | 150 | 230 | |

| Motor power | KW | 11 | 15 | 18.5 | 18.5 | |

| Blanking hole | mm | Non-standard customization | ||||

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设