189-1422-7001

![]() PRODUCT FEATURES

PRODUCT FEATURES

1. Using Taiwan, China imported hydraulic system, more stable hydraulic system, more safe and reliable

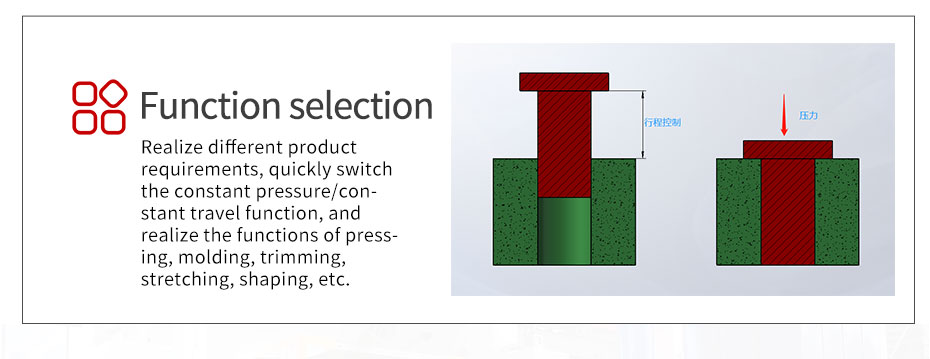

2. Pressure, travel, pressure can be adjusted according to pressing process requirements

3. Four columns with high strength material, surface coated hard chromium, good wear resistance

4. Activity plate, workbench with optional or no feeding cylinder, suitable for a variety of products feeding requirements

5. PLC programming circuit design, touch screen operating system, realize digital control.

![]() SCOPE OF APPLICATION

SCOPE OF APPLICATION

1. Auto parts, LED light radiator and hardware tools and other products hot forging molding, imprint

2. Metal or non-metal shallow stretching, plastic, etc.

![]() TECHNICAL PARAMETER

TECHNICAL PARAMETER

project | UNIT | 100T | 200T | 300T | 500T | 650T | 800T | 1000T | 1500T | 2000T | 3000T | |

Master cylinder | Nominal force | Ton | 100 | 200 | 300 | 500 | 650 | 800 | 1000 | 1500 | 2000 | 3000 |

Maximum stroke | mm | 350 | 350 | 350 | 350 | 500 | 500 | 500 | 500 | 500 | 500 | |

Maximum opening height | mm | 550 | 600 | 700 | 900 | 1000 | 1000 | 1200 | 1400 | 1500 | 1500 | |

Blank holder master cylinder | Nominal force | Ton | 15 | 30 | 30 | 40 | 50 | 50 | 50 | 60 | 100 | 1000 |

Maximum stroke | mm | 150 | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Unloading cylinder | Nominal force | Ton | 3 | 3 | 3 | 3 | 5 | 5 | 5 | 5 | 5 | 5 |

Maximum stroke | mm | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

Slide stroke speed | down | mm/s | 260 | 270 | 260 | 250 | 210 | 200 | 190 | 190 | 190 | 190 |

drawing | mm/s | 10/25 | 10/15 | 8/15 | 8/15 | 8/16 | 8/16 | 8/16 | 7/9 | 6/8 | 4/6 | |

return trip | mm/s | 250 | 240 | 230 | 230 | 200 | 190 | 180 | 180 | 180 | 190 | |

Effective area of workbench | Left and right (inside the column) | mm | 550 | 550 | 550 | 650 | 750 | 850 | 1000 | 1200 | 1500 | 1500 |

Front and rear (edge) | mm | 600 | 600 | 650 | 700 | 800 | 950 | 1060 | 1400 | 1500 | 1500 | |

Overall dimensions of the machine | Left and right L-R | mm | 1550 | 1830 | 2150 | 2250 | 2370 | 2550 | 2950 | 3500 | 3900 | 4200 |

Front and rear F-B | mm | 1260 | 1360 | 1550 | 1850 | 1800 | 1850 | 2200 | 2400 | 2600 | 2900 | |

High H | mm | 2580 | 2750 | 3020 | 3550 | 3700 | 3950 | 4100 | 5250 | 5650 | 5850 | |

Motor power | KW | 7.5 | 11.6 | 16.4 | 24.5 | 31 | 31 | 49.6 | 31*2 | 49.6*2 | 49.6*3 | |

weight | Kg | 4500 | 3800 | 4500 | 7800 | 11500 | 13500 | 21000 | 25000 | 33000 | 42000 | |

Oil consumption | L | 350 | 400 | 450 | 500 | 800 | 800 | 1000 | 1300 | 1500 | 1800 | |

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设