189-1422-7001

![]() Product use

Product use

This machine is suitable for various stamping processes such as press fitting, bending, forming, blanking, turning over, etc., especially for the following fields: automobile parts: motor, body covering parts, brake pads, oil tank, chassis, axle housing, bumper; Household appliances: kitchen appliances, stator laminations, etc.

![]() Product features

Product features

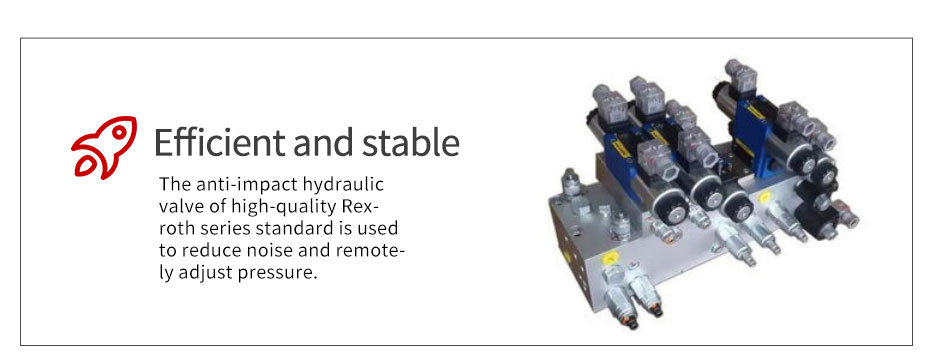

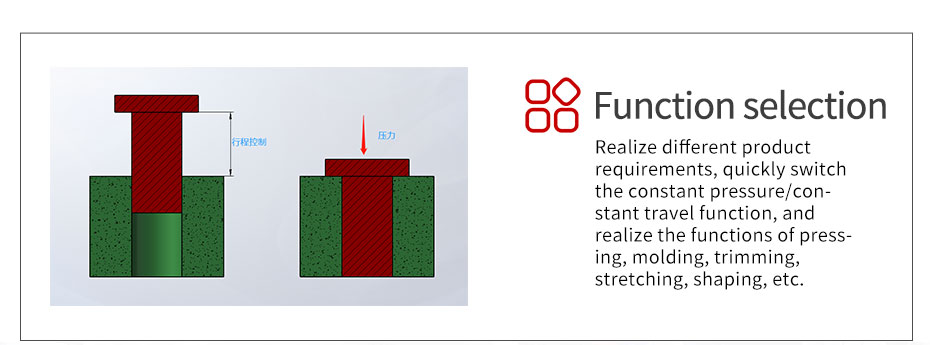

The machine adopts a C-type structure with a hydraulic cylinder mounted on it. The imported high-pressure gear pump, servo motor and driver are used to control the action. The system is installed with high-precision pressure sensor and displacement control ruler. It has independent power mechanism and electrical system, maintenance control PLC programmable controller programming, button centralized control, Siemens touch screen modification and preparation of process parameters. It can realize the process functions of constant travel and constant pressure, and has two operation modes: inching and single-cycle automatic. The upper and lower limit of the main cylinder and the fast and slow speed control are controlled by the magnetic grid ruler. The process parameters can be set on the touch screen. The operation is simple and safe. The cylinder is controlled by the pressure sensor to display the pressure.

![]() Product advantages

Product advantages

1. Energy saving: significantly save energy, improve efficiency, and save energy up to 30-50%.

2. Environmental protection: reduce CO2 emissions and use costs.

3. Safety: servo motor braking speed is faster than ordinary motor.

4. Precision: the precision can reach one thread (0.001MM), and the working pressure and speed can be set arbitrarily on the operation display.

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设