189-1422-7001

![]() Product features

Product features

1. It adopts the overall frame structure design, and is subject to artificial aging, polishing and antirust treatment, with strong rigidity and small deformation.

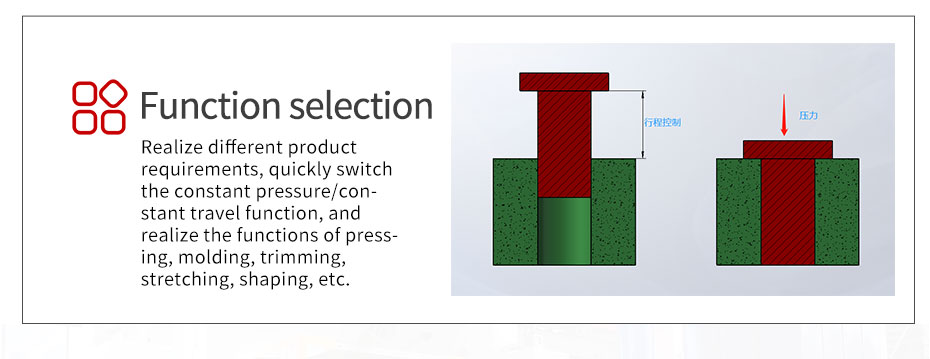

2. The key hydraulic electrical appliances adopt German, American and Japanese famous brand products with guaranteed quality.

3. Slider type movable plate downward speed, high production efficiency.

4. The pressure, stroke and pressurization time can be adjusted according to the pressing process requirements.

5. Large table, large mold space, eight long guide rail guide, high movement accuracy.

6. The fixed-point and quantitative thin oil continuous circulation cooling and lubrication system makes the machine operate more safely.

![]() Scope of application

Scope of application

1. Stretching and molding of auto parts, new energy radiators, household appliance parts, kitchen appliances, etc.

2. It is especially suitable for drawing, forming and other processes of special-shaped products.

3. Metal or non-metal stamping, stretching, bending, flanging, forming and other stamping.

![]() TECHNICAL PARAMETER

TECHNICAL PARAMETER

project | UNIT | 500T | 650T | 800T | 1000T | 1500T | 2000T | 3000T | 5000T | |

Master cylinder | Nominal force | KN | 5000 | 6500 | 8000 | 10000 | 15000 | 15000 | 30000 | 50000 |

Maximum stroke | mm | 400 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | |

Maximum opening height | mm | 900 | 1000 | 1200 | 1400 | 1500 | 1500 | 1500 | 1500 | |

lower cylinder | Nominal force | KN | 400 | 500 | 500 | 600 | 1000 | 1000 | 1000 | 1000 |

Maximum stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Unloading cylinder | Nominal force | KN | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

Maximum stroke | mm | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

Slide stroke speed | down | mm/s | 230 | 220 | 190 | 190 | 190 | 190 | 190 | 190 |

compression | mm/s | 2/13 | 2/10 | 2/10 | 2/10 | 2/10 | 2/10 | 2/10 | 2/10 | |

return trip | mm/s | 220 | 210 | 180 | 180 | 180 | 180 | 180 | 180 | |

Effective area of workbench | Left and right (inside the column) | mm | 750 | 850 | 1000 | 1200 | 1500 | 1500 | 1500 | 1500 |

Front and rear (edge) | mm | 800 | 1000 | 1060 | 1400 | 1500 | 1500 | 1500 | 1500 | |

Overall dimensions of the machine | Left and right L-R | mm | 1780 | 2760 | 2960 | 3200 | 3700 | 3900 | 4200 | 4500 |

Front and rear F-B | mm | 1870 | 2100 | 2300 | 2500 | 2800 | 3000 | 3000 | 3500 | |

High H | mm | 3700 | 4000 | 4400 | 4900 | 5600 | 6000 | 6200 | 6800 | |

Motor power | KW | 24.5 | 31 | 49.6 | 60 | 91 | 92 | 147 | 196 | |

weight | kg | 12000 | 14000 | 21000 | 25000 | 33000 | 41000 | 45000 | 520000 | |

Oil consumption | L | 800 | 800 | 1000 | 1300 | 1500 | 1800 | 2000 | 2200 | |

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设