189-1422-7001

![]() Product features

Product features

1. Adopt imported servo hydraulic system, more stable hydraulic system, more safe and reliable;

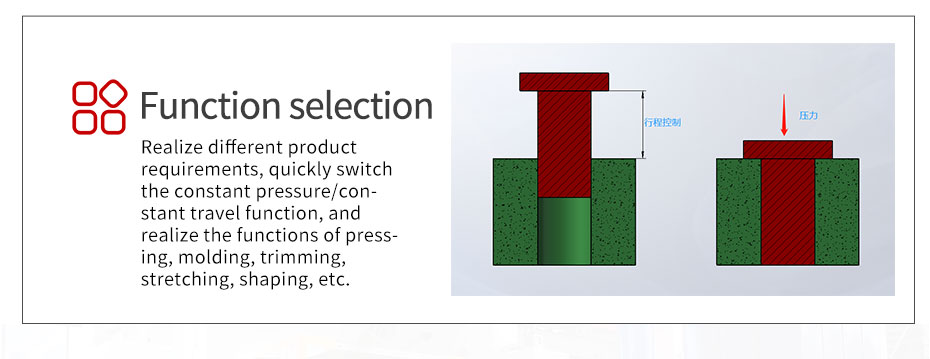

2. The pressure, stroke and pressure holding can be adjusted according to the pressing process requirements;

3. The four columns are made of high-strength materials, with hard chrome plating on the surface and good wear resistance;

4. The movable plate and worktable are equipped with optional or no material return cylinder, which is applicable to the material return requirements of various products;

5. PLC programming circuit design, touch screen operation system, digital control;

![]() Scope of application

Scope of application

1. Auto parts, LED light radiator and hardware tools and other products are cold extruded and stamped;

2. Shallow stretching and shaping of metal or nonmetal

![]() TECHNICAL PARAMETER

TECHNICAL PARAMETER

project | UNIT | 100T | 200T | 300T | 500T | 650T | 800T | 1000T | 1500T | 2000T | 3000T | |

Master cylinder | Nominal force | Ton | 100 | 200 | 300 | 500 | 650 | 800 | 1000 | 1500 | 2000 | 3000 |

Maximum stroke | mm | 350 | 350 | 350 | 350 | 500 | 500 | 500 | 500 | 500 | 500 | |

Maximum opening height | mm | 550 | 600 | 700 | 900 | 1000 | 1000 | 1200 | 1400 | 1500 | 1500 | |

Blank holder master cylinder | Nominal force | Ton | 15 | 30 | 30 | 40 | 50 | 50 | 50 | 60 | 100 | 1000 |

Maximum stroke | mm | 150 | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

Unloading cylinder | Nominal force | Ton | 3 | 3 | 3 | 3 | 5 | 5 | 5 | 5 | 5 | 5 |

Maximum stroke | mm | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | |

Slide stroke speed | down | mm/s | 260 | 270 | 260 | 250 | 210 | 200 | 190 | 190 | 190 | 190 |

drawing | mm/s | 10/25 | 10/15 | 8/15 | 8/15 | 8/16 | 8/16 | 8/16 | 7/9 | 6/8 | 4/6 | |

return trip | mm/s | 250 | 240 | 230 | 230 | 200 | 190 | 180 | 180 | 180 | 190 | |

Effective area of workbench | Left and right (inside the column) | mm | 550 | 550 | 550 | 650 | 750 | 850 | 1000 | 1200 | 1500 | 1500 |

Front and rear (edge) | mm | 600 | 600 | 650 | 700 | 800 | 950 | 1060 | 1400 | 1500 | 1500 | |

Overall dimensions of the machine | Left and right L-R | mm | 1550 | 1830 | 2150 | 2250 | 2370 | 2550 | 2950 | 3500 | 3900 | 4200 |

Front and rear F-B | mm | 1260 | 1360 | 1550 | 1850 | 1800 | 1850 | 2200 | 2400 | 2600 | 2900 | |

High H | mm | 2580 | 2750 | 3020 | 3550 | 3700 | 3950 | 4100 | 5250 | 5650 | 5850 | |

Motor power | KW | 7.5 | 11.6 | 16.4 | 24.5 | 31 | 31 | 49.6 | 31*2 | 49.6*2 | 49.6*3 | |

weight | Kg | 4500 | 3800 | 4500 | 7800 | 11500 | 13500 | 21000 | 25000 | 33000 | 42000 | |

Oil consumption | L | 350 | 400 | 450 | 500 | 800 | 800 | 1000 | 1300 | 1500 | 1800 | |

Service Hotline

189-1422-7001Copyright @ 2012 Wuxi KLT Precision Hydraulic Machinery Factory 苏ICP备2022018137号 技术支持:无锡网站建设